I. Introduction

Shanxi Asian American Daning Energy Co., Ltd. is a joint venture by the Asian American Coal Co., Ltd., Shanxi Lanhuakechuang Co., Ltd. and Jincheng Coal Transportation and Marketing Branch tripartite co-operative joint-stock enterprises, is China's first Sino-foreign joint venture modern coal enterprises. Asian American Daning mine, its an annual output of 400 tons of large modern mine, the main transport system of the need to transform the underground West End, the total length of 1296m. (Specific diagram below).

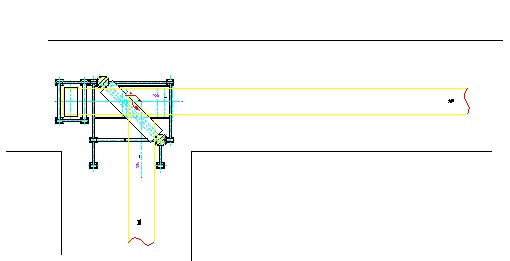

East-west direction has a belt conveyor, the length of 1084m, technical parameters are as follows: Model: DTL160/500/2 * 400, bandwidth: 1600mm, volume: 5000t / h, with speed: 4.3m / s installed power:2 * 400kW, system transport is shown schematically in Figure 1. Complicated due to the change to the presence of the original transport system, a belt conveyor to be able to solve the transport distance, in the north-south direction in the layout of a same type of belt conveyor.

This will bring several negative factors:

1) More than one belt conveyor, the motor power of the whole transport system to increase the 2 * 400kW, making underground power supply and distribution system complexity, while increasing the number of power distribution equipment;

2) Increased power consumption in the production process, the production cost of the large increase in degree of convergence;

3) More than a single belt conveyor, will manage and maintain the larger difficulties, while increasing maintenance costs.

4) Due to a power point, would need an additional operation workers, increased job setting is not conducive to the less mention efficiency.

After extensive research, we decided to transform the original transport system, the turning point at DZ-Ⅳ B1600 × 90 ° belt conveyor turning device using the Xuzhou TIANKE Machinery Manufacturing Co., Ltd. production. (Figure 2)

Second, the belt conveyor turning device Introduction

Belt conveyor turning device by turning the drum, bend pulley, buffer roller group, Pinto roller, rack, cleaning, backgauge device components, its structure is shown schematically in Figure 3.

Come from the direction of the tail of the tape through the upper steering drum turning, then bend pulley redirecting change back tape leading to the nose, coal while steering reproduced, the change falls backwards tape , was transported to the nose. Return with returned from the nose, then bend pulley by turning roller steering, and leading to the tail.

The core technology of the turning device is steering cylinder, steering cylinder fixed on the rack, turn to the outer circumference of the drum line, layout a certain rotation with the tape running Shaped planetary roller, shaped planetary roller radial force without bear axial force, in order to ensure the normal operation of the tape.

Turning device has the following characteristics:

1.Saving jobs setup, installation, use, maintenance is simple

2.The device less initial investment, saving the purchase and installation costs of the belt conveyor

3.Energy-saving effect is remarkable: due to the reduction of installed capacity, can save a lot of power consumption during operation.

4.Operates under braking problems, improve system security, and reliability.

5. Low operating costs: equipment disassembly easy transportation, long-term repeated use; system simplified, low failure rate; the Provincial people, energy-saving, low maintenance costs, significant economic benefits.

DZ-Ⅳ B1600 × 90 ° belt conveyor turning device in effect:

The improved scheme using a belt conveyor is equipped with DZ-Ⅳ type belt conveyor turning device, simplifying the transport system, the considerable economic benefits. The system layout is shown in Figure III.

1.About 8.52 million yuan investment to reduce belt conveyors and related equipment.

2.To reduce the installed capacity of 400kW, an annual electricity savings of about 158 million.

3.The transport system to simplify and reduce maintenance costs, reduce the comprehensive maintenance cost of about $ 50,000 per year.

IV Conclusion:

The belt conveyor the turning device greatly expand the scope of its application, breaking the belt conveyor can only do straight line running history. Provides a practical way to simplify the transport system. 1600 belt conveyor corner transport transformation success, not only to the coal mine production has created tremendous benefits, but also create good conditions for coal mine safety.